Pump & Motor Systems Database Forms Guidelines Page

This is a

Guidelines

Page

for the Pump Database Form. In this document you will find a supplementary

information for the data fields required in the Pump Database Form. Please see

below example of what is included in this page:

·

Sources are not in any order of priority

·

Units may not be applicable for certain data

fields.

·

There are several references listed throughout

the document, please use them if more information is required.

This document should be the first reference if you have

questions regarding data fields. If you require more information, please

communicate with your Point of Contact

listed on the information page.

Regards,

Technical Support

Group

Contents

I. General

Data

.

2

II. Pump Specifications.

3

III. Motor Specifications.

6

IV. Installation Details.

8

V. Accessories Installed.

12

VI. Customer Service Details.

14

1. Region | Source: Given

Region

(Assigned by Kinder Morgan) in which Terminal is located.

2. Terminal (GeoLoc) | Source: Given

Terminal (Assigned

by Kinder Morgan) in which Pump & Motor System is located.

3. Location | Source: Given

Location (Assigned by Kinder Morgan) within the Terminal where Pump & Motor System is located.

4. Visibility | Source: Site visit

Identify the level of visibility of the Pump & Motor System in the area where it is situated.

·

High – Pump is highly visible

·

Medium – Pump is somewhat visible

·

Low – Pump is in low visibility area

We would like to know how visible the Pump & Motor System is to personnel within the Terminal.

This is important data as the chances for those individuals to identify issues the Pump & Motor System may have increases the more visible it is.

Visibility should incorporate the frequency of walk-arounds by facility personnel.

5. Description | Source: Given

Brief

description of Pump & Motor System functionality, given by Kinder Morgan.

6. Status | Source: Given

The status

of the Pump & Motor System, given by Kinder Morgan.

7. P&ID Number | Source: Maximo,

Engineering department

The P&ID

drawing number associated with the Pump & Motor System, given by Kinder Morgan.

8. Maximo Asset Number | Source: Given

Pump Maximo Asset

Number assigned by Kinder Morgan. Each asset will have its own unique asset

number.

9. Maximo Asset Tag | Source: Given

Pump Maximo Asset

Tag assigned by Kinder Morgan.

This tag number will be unique for the

Terminal it’s in, but may not be a unique tag number for all Kinder Morgan

assets.

10. Manufacturer | Source: Maximo,

P&ID, Site visit

Manufacturer

of the pump.

11. Model | Source: Maximo, P&ID,

Site visit

Model of the

pump, assigned by the Manufacturer.

12. Serial | Source: Maximo, P&ID,

Site visit

Serial

number of the pump, assigned by the Manufacturer.

13. Class SubType |

Source:

Maximo, P&ID, Manufacturer Site visit

Select the

class sub type for the pump.

We require a minimum of a second level

selection in red (example: PD_REC, CE_VERT_MULTI).

It would be ideal to identify the third level selection for positive

displacement pumps, but it is not required. If you determine that a pump is a rotary

pump, but do not know which kind of rotary pump, please select PD_ROT.

PD -

Positive Displacement

I.

PD_RO -

Rotary

a.

PD_RO_IG

-

Internal Gear

b.

PD_RO_LOBE

-

Lobe

c.

PD_RO_SCREW

-

Screw

d.

PD_RO_SB

-

Shuttle Block

e.

PD_RO_FV

-

Flexible Vane

f.

PD_RO_SV

-

Sliding Vane

g.

PD_RO_CP

-

Circumferential Piston

h.

PD_RO_FI

-

Flexible Impeller

i.

PD_RO_HTR

-

Helical Twisted Roots

j.

PD_RO_LR

-

Liquid-Ring

k.

PD_RO_PER

-

Peristatic

l.

PD_RO_HYD

-

Hydraulic

II.

PD_RE -

Reciprocating

a.

PD_RE_PIS

-

Piston

b.

PD_RE_PLU

-

Plunger

c.

PD_RE_DIAP

-

Diaphragm

III.

PD_LIN -

Linear

a.

PD_LIN_ROP

-

Rope

b.

PD_LIN_CHA

-

Chain

CE -

Centrifugal

I.

CE_VERT -

Vertical

Single-Stage

II.

CE_VERT_MULTI -

Vertical

Multi-Stage

III.

CE_HORIZ -

Horizontal

Single-Stage

IV.

CE_HORIZ_MULTI -

Horizontal

Multi-Stage

V.

CE_SUB -

Submersible

VAC – Vacuum

14. Last Re-build Year | Source: Maximo,

Maintenance department

This data field is not considered mandatory

Year that

pump was last re-built. If pump has not undergone any re-builds then the year

that pump was installed.

A pump is considered re-built when it comes out of service and undergoes mechanical repairs.

15. Max. Pump Capacity | Source: Maximo,

P&ID, Manufacturer, Site visit |

Units:

Gallons / Minute (gpm)

Maximum permissible

flow rate through the pump without causing pump damage.

[1]

Maximum flow rate (Qmax):

maximum permissible flow rate at which the pump can be continuously operated

without suffering any damage at the rotational speed.

Note: Pump

flow rate can vary with fluid properties.

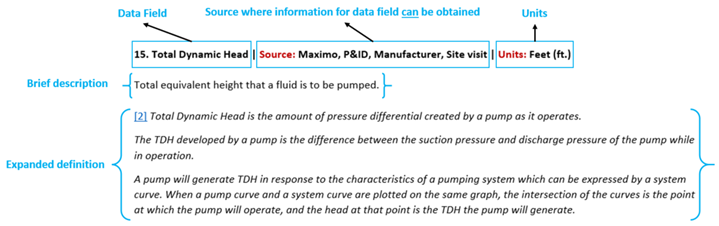

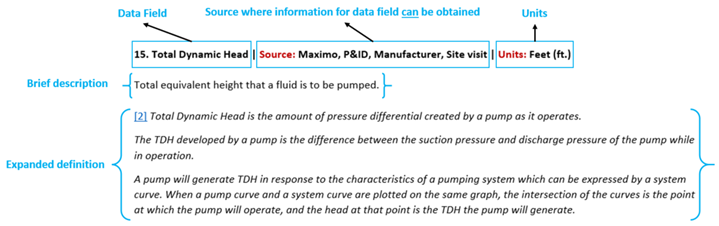

16. Total Dynamic Head | Source: Maximo,

P&ID, Manufacturer, Site visit |

Units:

Feet (ft.)

Total

equivalent height that a fluid is to be pumped.

[2]

Total Dynamic Head is the amount of

pressure differential created by a pump as it operates.

The TDH developed by a

pump is the difference between the suction pressure and discharge pressure of

the pump while in operation.

A pump will generate

TDH in response to the characteristics of a pumping system which can be

expressed by a system curve. When a pump curve and a system curve are plotted

on the same graph, the intersection of the curves is the point at which the

pump will operate, and the head at that point is the TDH the pump will

generate.

17. Inlet Size | Source: Maximo,

P&ID, Manufacturer, Site visit |

Units:

Inches (in.)

Inlet

diameter of the pump.

18. Outlet Size | Source: Maximo,

P&ID, Manufacturer, Site visit |

Units:

Inches (in.)

Outlet

diameter of the pump.

19. Impeller Diameter| Source: Maximo,

P&ID, Manufacturer, Site visit |

Units:

Inches (in.)

Diameter of

the pump impeller.

[14]

Normally,

pump vendors provide a range of impeller diameters suitable for a pump.

Impeller diameters are determined based on required head at design point. The

pump manufacturer will then trim the impeller to the required diameter.

20. Pump Casing Material | Source: P&ID,

Manufacturer, Site visit

The housing

material for the pump.

[3]

Pump

casings serve to seal off the inside of the pump to atmosphere to prevent

leakage and retain pressure. In the case of

centrifugal pumps

, they

surround the pump rotor which transmits energy to the fluid handled via

the

impeller

(s)

mounted on the rotating shaft.

In the case of

positive displacement

pumps

, they surround the rotary or reciprocating

displacement elements (e. g. one or more pistons).

21. Pump Impeller Material | Source: P&ID,

Manufacturer, Site visit

Impeller material

for the pump.

Impeller material can provide information on

wear and tear.

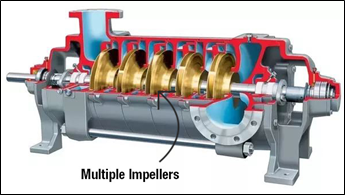

22. Stage | Source: Maximo, P&ID,

Manufacturer, Site visit

Number of

stages the pump has.

·

5 –

5

stage pump

·

4 –

4

stage pump

·

3 –

3

stage pump

·

2 –

2

stage pump

·

1 –

1

stage pump

·

Other –

Other

number of stages

·

N/A

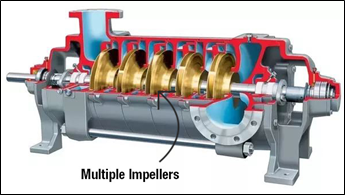

[4]

What is a multi-stage pump?

A pump that contains

different stages within the piping system where force is applied to the water.

Each stage consists of one impeller as well as its accompanying diffusion

components. The term “multistage” is usually used in reference

to centrifugal pumps.

In many cases, these

pumps are referred to in terms of how many stages they contain. For example, a

pump with four stages might be referred to as a four-stage pump, or one with 10

stages would be referred to as a ten-stage pump.

Figure

1

23. Photo of Pump Tag | Source: Site

visit

Attach a

photograph of the pump tag (1 photo).

24. Photo of Pump Body | Source: Site

visit

Attach a

photograph of the pump body (1 photo).

25. Maximo Asset Number2 | Source: Maximo,

P&ID, Site visit

Motor Maximo

Asset Number assigned by Kinder Morgan. Each asset will have its own unique

asset number.

26. Maximo Asset Tag2 | Source: Maximo,

P&ID, Site visit

Motor Maximo

Asset Tag assigned by Kinder Morgan.

This tag number will be unique for the

Terminal it’s in, but may not be a unique tag number for all Kinder Morgan

assets.

27. Manufacturer2 | Source: Maximo,

P&ID, Site visit

Manufacturer

of the motor.

28. Model2 | Source: Maximo, P&ID,

Site visit

Model of the

motor, assigned by the Manufacturer.

29. Serial2 | Source: Maximo, P&ID,

Site visit

Serial

number of the motor, assigned by the Manufacturer.

30. Frame | Source: Manufacturer, Site visit

Frame size

for motor housing.

The Manufacturer will typically assign the

motor a frame value, containing a combination of both letters and numbers.

31. Last Re-Build Year2 | Source: Maximo,

Maintenance department |

Units:

Year

This data field is not considered mandatory

Year that motor

was last re-built. If motor has not undergone any re-builds then the year that

pump was installed.

A motor is considered re-built when it comes

out of service and undergoes repairs.

32. Motor Capacity | Source: Maximo,

P&ID, Manufacturer, Site visit |

Units:

Revolutions / Minute (rpm)

Rotational

speed of the motor.

[5]

Rotational speed (also called speed, or

speed of rotation) can be quantified as the number of revolutions a rotating

system makes within a defined period of time.

33. Horsepower | Source: Maximo,

P&ID, Manufacturer, Site visit |

Units:

Horsepower (hp)

Horsepower

rating of the motor.

[6]

Equation for determining horsepower:

P = Power, hp

Q = Flow Rate, gpm

S = Specific Gravity of fluid

H = Head Height, ft.

µ

= Efficiency Coefficient

34. Power Rating | Source: Maximo,

P&ID, Manufacturer, Site visit |

Units:

Volts (V)

Electric

potential of the motor.

[7]

Single-phase motors are available in both

115V and 230V models while 3-phase motors can operate at 230V and 460V, but how

can you know which operating voltage is right for your needs?

·

115V

motors can be connected to the average household outlet, and these single-phase

motors are ideal for home uses, particularly with our

beer

pump systems

.

·

230V

motors are available in both single- and 3-phase designs and require an

electrical connection like that used to power a clothes dryer. These motors can

bridge the gap between residential and industrial grades.

·

460V

motors are ideal for more industrial settings, allowing the same amount of

power to be delivered to a motor at a reduced current. Because of their

improved efficiency, these motors are available in 3-phase designs.

35. Photo of Motor Tag | Source: Site visit

Attach a

photograph of the motor tag (1 photo).

36. Photo of Motor Body | Source: Site visit

Attach a

photograph of the motor body (1 photo).

37. Alignment | Source: Maximo, Work

Orders, Maintenance department |

Units:

Year, mils/inch, mils/inch

This data field is not considered mandatory

Proof of

alignment (Pump to Motor). Please provide the last year the Pump & Motor System

was aligned, the recommended tolerance, and the alignment value.

[8]

Motor-Pump alignment is the process of

aligning shaft centerlines between a motor and a pump. The motor is the prime

mover, transferring power to the pump by the use of a coupling. This is

probably the most common configuration of coupled machines in industry.

In this type of

alignment, the motor is almost always the moveable machine, and the pump is the

stationary machine. In almost all cases, the pump is already piped up with

suction and discharge flanges, which means it can move only slightly, if at

all.

Proper shaft alignment is achieved by moving

the motor. The motor is shimmed vertically to achieve the proper elevation to

align it to the pump, both parallel (offset) and angular. The motor is them

moved horizontally to achieve proper horizontal placement for aligning the

shaft centerlines, both parallel and angular. The motor is moved horizontally

by the use of jacking bolts, or by the use of pry bars, hammers, or other

tools.

38. Classification | Source: Maintenance

department

We are asking for two criteria regarding vibration to be examined with two drop down lists:

Hazardous (or

classified) location of area.

·

C1,D1 –

Class

1, Div 1

·

C1,D2 –

Class

1, Div 2

·

C2,D1 –

Class

2, Div 1

·

C2,D2 –

Class

2, Div 2

·

C3,D1 –

Class

3, Div 1

·

C3,D2 –

Class

3, Div 2

·

Other –

Classified,

but not listed

·

N/A –

No

classification found or needed

Hazardous (or

classified) location of asset.

·

C1,D1 –

Class

1, Div 1

·

C1,D2 –

Class

1, Div 2

·

C2,D1 –

Class

2, Div 1

·

C2,D2 –

Class

2, Div 2

·

C3,D1 –

Class

3, Div 1

·

C3,D2 –

Class

3, Div 2

·

Other –

Classified,

but not listed

·

N/A –

No

classification found or needed

[9]

The hazardous area classification system

determines required protection techniques and methods for electrical

installations in the location.

Class/Division System

The

Class/Division/Group system is based on Article 500 of the National Electrical

Code (NEC) where

Class

Class defines

the general nature (or properties) of the hazardous material

in the surrounding atmosphere.

|

Class

|

Nature of Hazardous Material

|

|

Class

I

|

Hazardous because flammable

gases or vapors

are

present (or may be present) in quantities sufficient to produce explosive or

ignitable mixtures.

|

|

Class

II

|

Hazardous because combustible or conductive

dusts

are present (or

may be present) in quantities sufficient to produce explosive or ignitable

mixtures.

|

|

Class

III

|

Hazardous because ignitable

fibers

or flyings are

present (or may be present) in quantities sufficient to produce explosive or

ignitable mixtures.

|

Division

Division defines the

probability

of the hazardous material being present

in an ignitable concentration in the surrounding atmosphere.

|

Division

|

Probability of Hazardous Material

|

|

Division

I

|

The substance referred to by class has a

high

probability

of producing an explosive or ignitable

mixture due to it being present continuously, intermittently, or periodically

or from

the equipment itself under normal operating conditions.

|

|

Division

II

|

The substance referred to by class has a

low

probability

of producing an explosive or ignitable

mixture and is present only during abnormal conditions for a short period of

time - such as a container failure or system breakdown

|

39. Foundation | Source: Maintenance

department, Site visit

The type of

foundation that is installed with the Pump & Motor System. If there is any

damage, corrosion, and/or bolts are missing please make a note of it.

·

Bolted

·

Bolted with Epoxy

·

Bolted with Grout

·

Not Bolted

·

Other

·

N/A

[10]

The

foundation of a stationary

centrifugal pump

must

be capable of absorbing the

forces

and

torques

transmitted

to it by the pump without shifting its position (see

Smooth running

); in

some cases it must also withstand forces transmitted by the associated

drive

and

piping

connected

to the pump (see

Pump nozzle load

).

The foundation's strength and vibration

behavior play a decisive role in ensuring its functional reliability.

40. Containment | Source: Site visit

Containment

is present for Pump & Motor System.

·

Yes -

containment

is present

·

Yes, to be reviewed. – containment is present, but needs to be further reviewed

·

No -

no

containment present

Containment is provided for Pump & Motor

System to capture spills or product releases.

41. Re-circulation / By-pass | Source: P&ID,

Site visit

Re-circulation

/ bypass is present for pump system:

·

Yes –

Re-circulation back to the pump

·

Yes –

Re-circulation back to the source

·

Yes –

Bypass the pump

·

No –

Re-circulation / Bypass not present

Ability to continue product movement through

a secondary pipeline around pump.

42. Reducer Proper Installation | Source: P&ID,

Site visit

Proper installation

of reducer:

·

Yes –

Properly

installed

·

No –

Not

properly installed

·

N/A –

Not

applicable

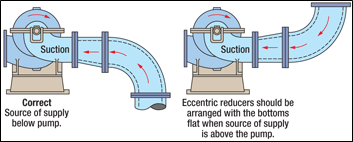

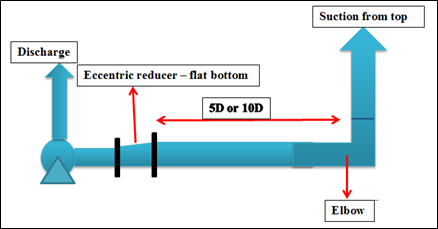

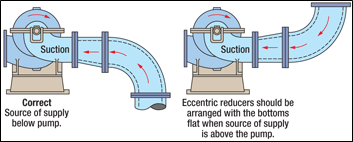

[11]

Eccentric

reducer

is recommended for

horizontal flow to the pump. This configuration prevents are pocket

accumulation at the upstream end of the reducer. Concentric reducer is recommended for the vertical inlet (suction)

piping or horizontal installations where there is no potential for air vapor

accumulation.

When the source of

supply is above the pump, then the eccentric reducers must be placed with the

flat side down. When the source of supply is below the pump, then the

eccentric reducers must be placed with the flat side up.

Figure

2

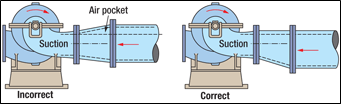

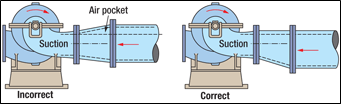

In case of long horizontal pipe runs, air pockets are avoided by

installing the eccentric reducer with the flat side up.

Figure

3

Figure

4

- Concentric Reducer

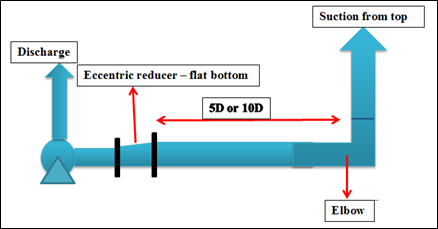

43. Intake Line Fittings Allowance | Source: Calculation | Units: Inches (in.)

Calculation

(Pump inlet diameter * 5).

[11]

Pumps, and especially centrifugal pumps,

work most smoothly and efficiently when the fluid is delivered in a surge-free,

smooth, laminar flow. Any form of turbulence reduced efficiency and increases

wear and tear on the pump’s bearings, seals and other components.

ANSI/HI 9.8 American

National Standard for Pump Intake Design (P21,1998)

states, “There shall be no flow disturbing fittings (such as partially open

valves, tees, short radius elbows, etc.) closer than five suction pipe

diameters from the pump. Fully open, non-flow disturbing valves, vaned elbows and reducers are not considered flow

disturbing fittings.” This standard eliminates any reference to the possible

flow distribution that could be generated by the reducer.

The concept is simple though, ensure stable and uniform flow onto the

impeller eye. This results in fewer pump failures over the life of the pump due

to vibration caused by flow induced turbulence.

Figure

5

In case several improperly specified parameters

come into the equation (e.g. viscosity changes etc),

then it would be prudent to install as many as ten suction pipe diameters of

straight piping next to the reducer inlet flange. A number ranging between five

(5) to ten (10) suction pipe diameters of straight pipe run is typically the

recommended value in published technical literature.

Sometimes

due to space constraints, it’s just not possible to make provision for a

sufficient settling distance in the pipework before the pump. In these cases,

use an inline flow conditioner or straightener.

44. Intake Line Fitting (Distance from Pump) |

Source:

Site visit

Units:

Inches (in.)

Actual

distance from pump inlet to nearest line fitting. Please refer to 43. Intake Line Fittings Allowance for

educational description.

45. Photo of Pump/Motor System| Source: Site

visit

Attach a

photograph of the Pump & Motor System (1 photo).

46. Vibration | Source: P&ID, Site

visit

We are

asking for two criteria regarding vibration to be examined with two drop down

lists:

Vibration

sensors are properly installed for Pump & Motor System:

·

Yes –

Installed

·

No –

Not

installed

Vibration

detected on Pump & Motor System

(If “Yes”, please

explain how it was measured and

documented in the notes section

& please submit attachment)

:

·

Yes, Documented and Measured

·

Yes, Measured

·

No

If you have

responded “yes” to the second drop-down list (Vibration detected on Pump &

Motor System), please explain how it

was measured and documented in the

notes

section & please submit attachment. Please identify the data field

number “46.”.

[12]

Vibration monitoring of critical and auxiliary

pumping systems helps improve machine reliability, safety and production

capability. Pumps produce vibrations indicative of running condition, incipient

faults and component failure. These vibrations appear at specific frequencies

across a wide spectrum.

Industrial

piezoelectric accelerometers provide the dynamic and frequency ranges required

for complete pump monitoring. Vibration is an integral part of an effective,

predictive maintenance program, enabling the early detection of failure modes

such as impeller erosion, pump imbalance, shaft looseness, coupling problems

and cavitation. The vibration sensor that is for the application will depend on

the frequencies of interest and the type of pump being monitored.

47. Bearing Temperature Thermocouples | Source: P&ID, Site Visit

Bearing Temperature Thermocouples are properly installed for

Pump & Motor System.

·

Yes –

Installed

properly

·

No –

Not

properly installed

[13]

Condition monitoring has proven important in

the installation and maintenance of all types of turbomachinery throughout the

past 30 to 40 years. Babbitt bearing temperature is primarily important because

bearings are the critical links between the rotating and stationary components

in a machine. If temperatures are taken in the correct location with respect to

the direction of bearing load, to direction of shaft rotation and to the

distance of the tip of the sensor from the bearing running surface, then

Babbitt metal temperatures can be the best indicators of a bearing's operating

condition.

Data analysis

from many bearing tests, prototype turbomachinery tests and day-to-day

operation has pinpointed the locations of greatest sensitivity for installing temperature

sensing probes. In most bearing applications, the current state-of-the-art

technology uses some type of electrically variable tip at the end of a current

conducting set of wires. The wires provide a flexible connection to the outside

of the bearing while the sensor tip is engineered to the smallest practical

size for insertion into the bearing.

48. Flow Switch |

Source:

P&ID, Site Visit

Flow switch, Flow Indicator Transmitter (FIT), Pressure Indicator Transmitter (PIT) is installed downstream of the Pump & Motor System.

·

Yes –

Installed

·

No – Not Installed

49. Emergency Shutdown System | Source: P&ID,

Site Visit

Emergency

Shutdown System is properly installed for Pump & Motor System.

·

Yes – Installed

·

No –

Not

installed

[14]

The purpose of an Emergency Shutdown System

(ESD) is to provide a fail-safe independent control system that can shut down a

station and isolate it in the event of a pipeline rupture or a fire at the

station.

The ESD system

overrides any operating signals from the station or local controls and its

design therefore, needs to meet the requirements of both the regulatory regime

and the owner’s own design philosophies and criteria.

The ESD is the last line of defense to shut

down a station and must be able to perform its function even if the station has

lost normal power supply, has lost the ability to communicate with SCADA or in

the case of local control, system failure

.

50. Leak Detection System |

Source:

SCADA, Site Visit

Leak

detection system is properly installed for the Pump & Motor System.

·

Yes – Installed

·

No –

Not

Installed

Please

answer yes if there is a leak detection system installed for the Pump &

Motor System. Some examples of leak detection systems include Plan 65B Seal Leak Pot, HCD

Point Detector, and Slick Sleuth Detector.

51. Fire Protection System | Source: SCADA, Site Visit

We are

asking for three criteria regarding fire protection system to be examined with

three drop down lists:

Fire

protection system is installed for or near the Pump & Motor System.

·

Yes –

Installed

·

No –

Not

Installed

Proximity of

fire protection systems to Pump & Motor System.

·

Within 10 Feet

·

Between 10 and 50 Feet

·

Greater than 50 Feet

·

N/A –

Not

Installed

System

response

·

Automated System

·

Manual System

·

N/A –

Not

Installed

First, we want to know if there is a fire

protection system installed for or near the Pump & Motor System. If so, we

would like to know how close the fire protection systems (fire monitors, fire

truck hook ups, etc.) are to the Pump & Motor System.

52. In-service Product(s) | Source: Operations

department

Product that

flows through Pump & Motor System (If multiple, please separate by comma).

53. Max Flow Rate Desired | Source: Commercial

dept., Operations dept. |

Units:

Gallons / Minute (gpm)

Numerical

representation of the maximum desired flow rate.

This value is typically set by the

Commercial & Operations Department.

54. Actual Flow Rates | Source: Operations

dept., SCADA | Units: Gallons /

Minute (gpm)

Numerical

representation of the actual flow rates.

This value is the current operating flow

rate through the pump. This value can be gathered by Operations or by SCADA.

55. Maintenance History | Source: Maximo Report

Proof of Maintenance History. Please provide:

1. Total Corrective Maintenances (CM)

2. Year of last Corrective Maintenance (CM)

3. Preventive Maintenance (PM) assigned to pump

·

Yes

·

No

·

NA

References

[1]

Rotational

speed | KSB. (n.d.). Retrieved May 11, 2020, from

https://www.ksb.com/centrifugal-pump-lexicon/rotational-speed/191072

[2]

Total

Dynamic Head (TDH) Definition. (n.d.). Retrieved May

11, 2020, from

https://www.introtopumps.com/pump-terms/tdh-total-dynamic-head/

[3]

Germany, F.,

& Ksb Ag. (n.d.). Pump

casing. Retrieved May 11, 2020, from

https://www.ksb.com/centrifugal-pump-lexicon/pump-casing/191326/

[4]

Multistage Pumps. (n.d.).

Retrieved from

http://www.pumpscout.com/all-pump-types/multistage-pumps-ptid96.html

[5]

Germany, F.,

& Ksb Ag. (n.d.). Flow

rate. Retrieved May 11, 2020, from

https://www.ksb.com/centrifugal-pump-lexicon/flow-rate/191086/

[6]

Hydraulic

Pump Horsepower Equation - Engineers Edge. (n.d.).

Retrieved May 11, 2020, from

https://www.engineersedge.com/motors/pump_power_equation.htm

[7]

Which Motor

Voltage Do You Need? (2016, January 18). Retrieved May 11, 2020, from

https://www.marchpump.com/blog/which-motor-voltage-do-you-need/

[8]

Motor-pump

Alignment. (n.d.). Retrieved May 11, 2020, from

https://vibralign.com/resources/concepts/motor-pump-alignment/

[9]

Hazardous Areas Classification - North America. (n.d.). Retrieved from

https://www.engineeringtoolbox.com/hazardous-areas-classification-d_345.html

[10]

Pump

foundation | KSB. (n.d.). Retrieved May 11, 2020,

from

https://www.ksb.com/centrifugal-pump-lexicon/pump-foundation/191602

[11]

Theprocesspiping

. (2018, August 7). Pumps Suction Piping

- Eccentric Reducers & Straight Lengths. Retrieved from

https://www.theprocesspiping.com/pumps-suction-piping-eccentric-reducers-straight-lengths/

[12]

Klubnik, R., Meggitt Sensing

Systems, Mss, & Wilcoxon Research. (2011,

December 17). Pump Vibration Monitoring Basics. Retrieved May 11, 2020, from

https://www.pumpsandsystems.com/pump-vibration-monitoring-basics

[13]

Temperature

as Indicator of Bearing Operating Condition ... (n.d.).

Retrieved May 11, 2020, from

https://www.pumpsandsystems.com/temperature-indicator-bearing-operating-condition

[14]

Mohitpour

, M., Yoon, M., & Russell, J. (2012). Hydrocarbon Liquid

Transmission Pipeline and Storage Systems - Design and Operation. Asme Press.

Figures

Figure 1 - Multistage Pump

Guide. (n.d.). Retrieved from

https://www.castlepumps.com/info-hub/multistage-pump-guide/

Figure 2 -

Theprocesspiping

. (2018, August 7). Pumps Suction Piping - Eccentric Reducers

& Straight Lengths. Retrieved from

https://www.theprocesspiping.com/pumps-suction-piping-eccentric-reducers-straight-lengths/

Figure 3 -

Theprocesspiping

. (2018, August 7). Pumps Suction Piping - Eccentric Reducers

& Straight Lengths. Retrieved from

https://www.theprocesspiping.com/pumps-suction-piping-eccentric-reducers-straight-lengths/

Figure 4 –

Concentric Reducer. (n.d.). Retrieved from

https://www.shikharsteel.com/concentric-reducer-manufacturer-supplier.html

Figure 5 -

Theprocesspiping

. (2018, August 7). Pumps Suction Piping - Eccentric Reducers

& Straight Lengths. Retrieved from

https://www.theprocesspiping.com/pumps-suction-piping-eccentric-reducers-straight-lengths/